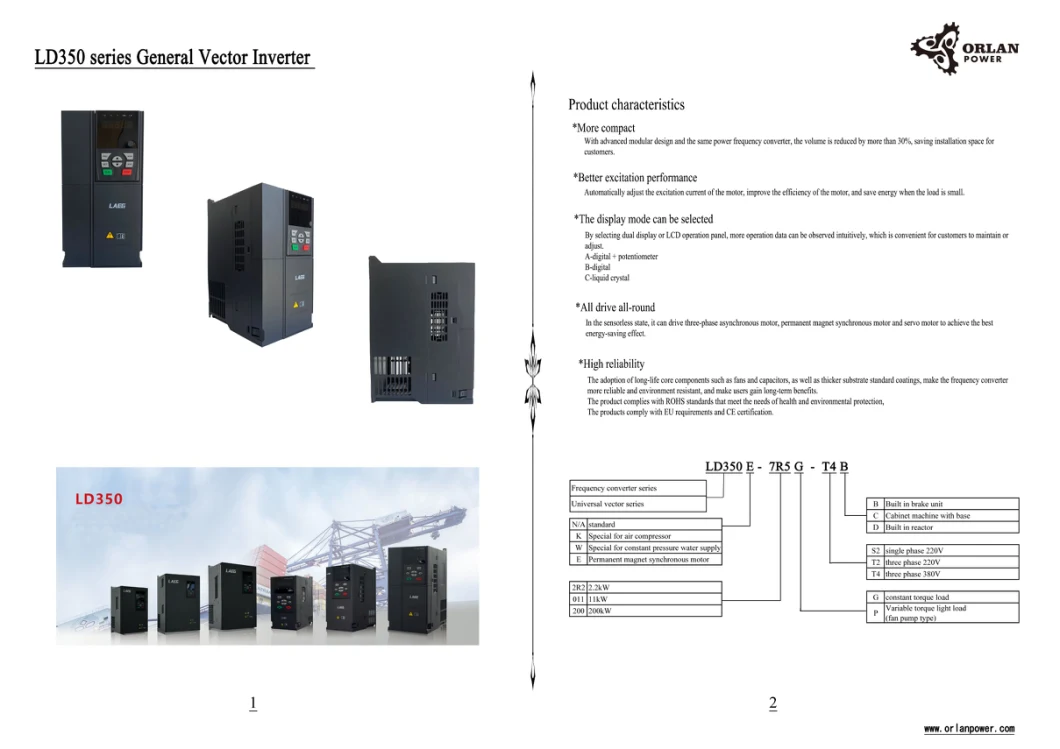

Three Phase Ld350 Series Vector Inverter 380V 5.5kw/7.5kw CPU Board

Three Phase Ld350 Series Vector Inverter 380V 5.5kw/7.5kw CPU Board

Description

Basic Info

| Model NO. | T4 5.5kw~7.5kw |

| Application | High-performance Transducer, Three Phase Transducer, General Transducer, Single-phase Transducer, High Frequency Converter Transducer |

| Output Type | Single |

| Principle of Work | V/F Control Transducer |

| Switch Mode | PWM Control |

| Main Circuit Type | Voltage |

| Voltage of Power Supply | Low Voltage Variable-Frequency Drive |

| Link of Transformation | AC-DC-AC Variable-Frequency Drive |

| Nature of DC Power | Voltage Variable-Frequency Drive |

| Function | Simple Type, Elevator Special, Textile Special, Constant Torque Universal Type |

| Transport Package | Cartoon |

| Trademark | LAEG |

| HS Code | 8504409930 |

| Production Capacity | 500 |

Product Description

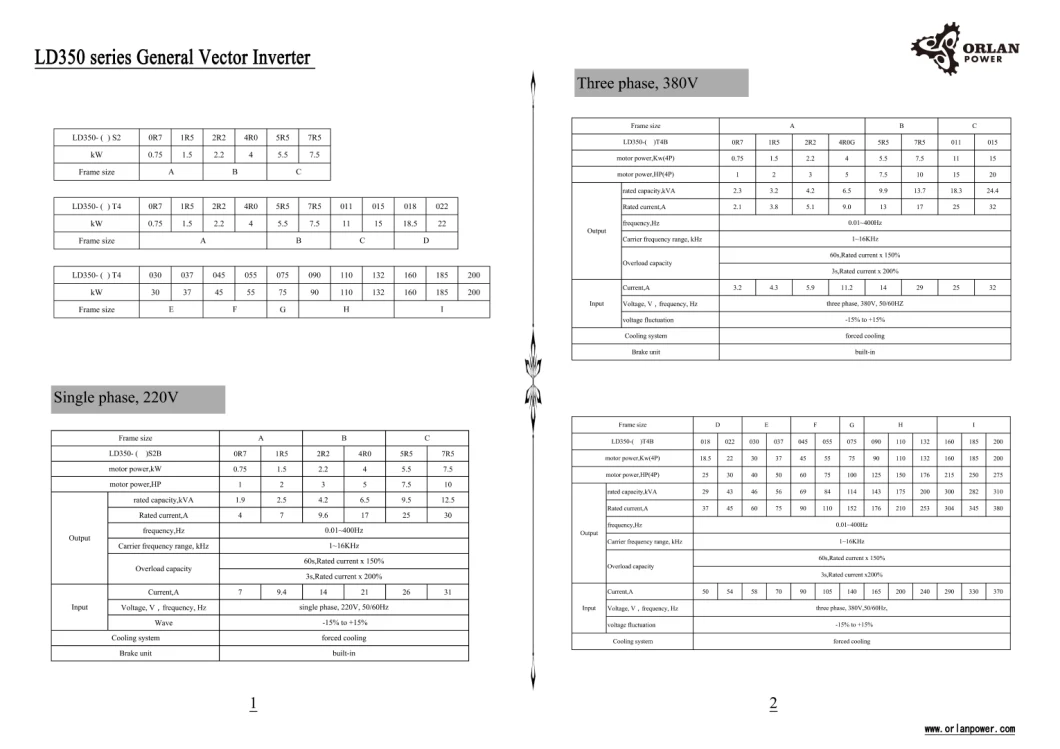

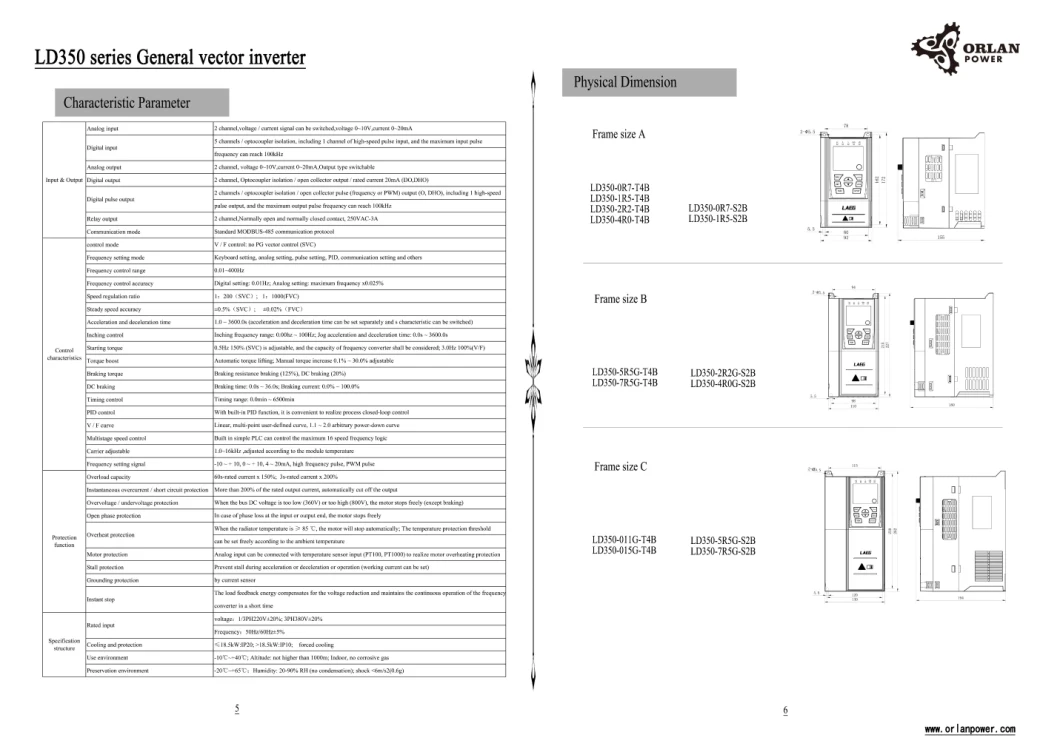

| Input & Output | Analog input | 2 channel,voltage / current signal can be switched,voltage 0~10V,current 0~20mA | ||||||

| Digital input | 5 channels / optocoupler isolation, including 1 channel of high-speed pulse input, and the maximum input pulse | |||||||

| frequency can reach 100kHz | ||||||||

| Analog output | 2 channel, voltage 0~10V,current 0~20mA,Output type switchable | |||||||

| Digital output | 2 channel, Optocoupler isolation / open collector output / rated current 20mA (DO,DHO) | |||||||

| Digital pulse output | 2 channels / optocoupler isolation / open collector pulse (frequency or PWM) output (O, DHO), including 1 high-speed | |||||||

| pulse output, and the maximum output pulse frequency can reach 100kHz | ||||||||

| Relay output | 2 channel,Normally open and normally closed contact, 250VAC-3A | |||||||

| Communication mode | Standard MODBUS-485 communication protocol | |||||||

| Control characteristics | control mode | V / F control: no PG vector control (SVC) | ||||||

| Frequency setting mode | Keyboard setting, analog setting, pulse setting, PID, communication setting and others | |||||||

| Frequency control range | 0.01~400Hz | |||||||

| Frequency control accuracy | Digital setting: 0.01Hz; Analog setting: maximum frequency x0.025% | |||||||

| Speed regulation ratio | 1:200(SVC); 1:1000(FVC) | |||||||

| Steady speed accuracy | ±0.5%(SVC); ±0.02%(FVC) | |||||||

| Acceleration and deceleration time | 1.0 ~ 3600.0s (acceleration and deceleration time can be set separately and s characteristic can be switched) | |||||||

| Inching control | Inching frequency range: 0.00hz ~ 100Hz; Jog acceleration and deceleration time: 0.0s ~ 3600.0s | |||||||

| Starting torque | 0.5Hz 150% (SVC) is adjustable, and the capacity of frequency converter shall be considered; 3.0Hz 100%(V/F) | |||||||

| Torque boost | Automatic torque lifting; Manual torque increase 0.1% ~ 30.0% adjustable | |||||||

| Braking torque | Braking resistance braking (125%), DC braking (20%) | |||||||

| DC braking | Braking time: 0.0s ~ 36.0s; Braking current: 0.0% ~ 100.0% | |||||||

| Timing control | Timing range: 0.0min ~ 6500min | |||||||

| PID control | With built-in PID function, it is convenient to realize process closed-loop control | |||||||

| V / F curve | Linear, multi-point user-defined curve, 1.1 ~ 2.0 arbitrary power-down curve | |||||||

| Multistage speed control | Built in simple PLC can control the maximum 16 speed frequency logic | |||||||

| Carrier adjustable | 1.0~16kHz ,adjusted according to the module temperature | |||||||

| Frequency setting signal | -10 ~ + 10, 0 ~ + 10, 4 ~ 20mA, high frequency pulse, PWM pulse | |||||||

| Protection function | Overload capacity | 60s-rated current x 150%; 3s-rated current x 200% | ||||||

| Instantaneous overcurrent / short circuit protection | More than 200% of the rated output current, automatically cut off the output | |||||||

| Overvoltage / undervoltage protection | When the bus DC voltage is too low (360V) or too high (800V), the motor stops freely (except braking) | |||||||

| Open phase protection | In case of phase loss at the input or output end, the motor stops freely | |||||||

| Overheat protection | When the radiator temperature is ≥ 85 ºC, the motor will stop automatically; The temperature protection threshold | |||||||

| can be set freely according to the ambient temperature | ||||||||

| Motor protection | Analog input can be connected with temperature sensor input (PT100, PT1000) to realize motor overheating protection | |||||||

| Stall protection | Prevent stall during acceleration or deceleration or operation (working current can be set) | |||||||

| Grounding protection | by current sensor | |||||||

| Instant stop | The load feedback energy compensates for the voltage reduction and maintains the continuous operation of the frequency | |||||||

| converter in a short time | ||||||||

| Specification structure | Rated input | voltage:1/3PH220V±20%; 3PH380V±20% | ||||||

| Frequency:50Hz/60Hz±5% | ||||||||

| Cooling and protection | ≤18.5kW:IP20; >18.5kW:IP10; forced cooling | |||||||

| Use environment | -10ºC~+40ºC; Altitude: not higher than 1000m; Indoor, no corrosive gas | |||||||

| Preservation environment | -20ºC~+65ºC;Humidity: 20-90% RH (no condensation); shock <6m/s2(0.6g) | |||||||

Prev: HPS off Solar Inverter Pure Sign Wave Inverter off Grid Solar Board 1200W 1.2kw 12VDC 230VAC PWM 50A

Next: 1500W 12VDC to 220VDC Pure Sine Wave on-Board Inverter

Our Contact

Send now